What is Spatial Computing?

Spatial computing is an innovative technological paradigm that merges the physical and digital worlds. It encompasses a variety of technologies, including augmented reality (AR), virtual reality (VR), and mixed reality (MR), allowing users to interact with both real and virtual objects in a cohesive environment.

Why is Spatial Computing Important?

As industries evolve, the need for immersive experiences becomes increasingly critical. Spatial computing provides a bridge for digital interaction and enhances how we engage with information—leading to transformative experiences across various sectors.

The Applications of Spatial Computing

Spatial computing is revolutionizing numerous fields:

- Healthcare: AR applications help surgeons visualize complex structures during surgery, thus improving precision and outcomes.

- Education: Interactive 3D models enhance learning engagement and retention rates for students.

- Real Estate: Virtual property walkthroughs provide potential buyers with immersive experiences without the need to be physically present.

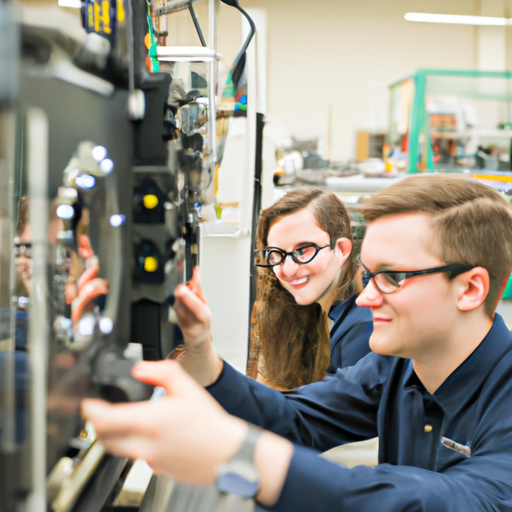

- Manufacturing: Digital twins enable companies to create virtual replicas of physical systems for better analysis and predictive maintenance.

How Spatial Computing Works

Spatial computing utilizes multiple technologies to create a coherent interaction between the user and digital content. Devices such as smartphones, head-mounted displays (HMDs), and tablets facilitate these experiences through sensors, cameras, and advanced software that tracks user movements and environmental data.

The Future of Spatial Computing

As the field continues to evolve, advancements such as 3D mapping and better processing capabilities are set to enhance the efficacy and reach of spatial computing applications. The integration of AI will further empower machines to understand and interact with their environments autonomously.

In conclusion, spatial computing is not just a trend; it’s the future of how we will interface with the world around us. As it becomes more prevalent, embracing its technology will be essential for individuals and businesses looking to stay ahead.

Conclusion

To sum up, spatial computing encompasses various technologies driving significant advancements across multiple industries. As we continue to explore its potential, it’s clear that spatial computing will redefine the interaction between the physical and digital realms.

If you’re interested in the latest trends in technology, subscribe to our blog for more insights into spatial computing and beyond!