Introduction

3D printing, also known as additive manufacturing, is rapidly transforming the landscape of industry and manufacturing. With its ability to create complex shapes and structures, 3D printing technology has gained traction in various sectors, from aerospace to healthcare. In this blog post, we will delve into the benefits and applications of 3D printing, and explore what the future holds for this groundbreaking technology.

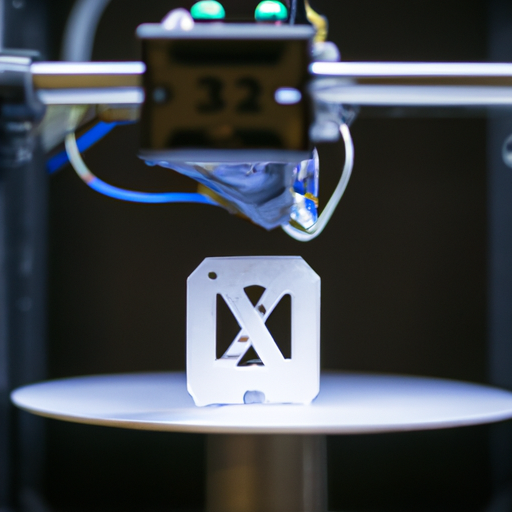

What is 3D Printing?

3D printing is a manufacturing process that creates three-dimensional objects from a digital design by layering materials. Unlike traditional manufacturing methods which often involve subtractive techniques (cutting away material), 3D printing builds up an object layer by layer, allowing for unparalleled design freedom and material efficiency.

Benefits of 3D Printing

- Reduced Waste: As an additive process, 3D printing minimizes material waste since objects are built layer by layer from only the necessary amount of material.

- Cost-Effective Prototyping: Designers can create prototypes quickly and at a lower cost compared to traditional methods, leading to faster iterations and innovations.

- Customization: 3D printing allows for high levels of customization, enabling businesses to produce personalized products that meet unique customer demands.

- Complex Designs: The technology supports the creation of intricate designs that would be impossible or extremely costly to produce using traditional manufacturing techniques.

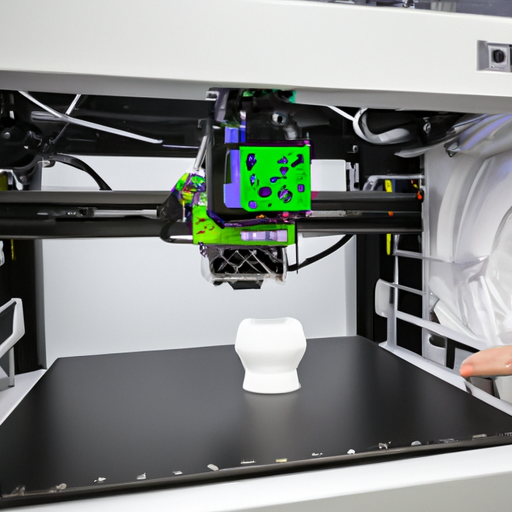

Applications of 3D Printing

3D printing has a wide range of applications across various industries:

- Aerospace: Components of aircraft can be fabricated with lightweight materials, improving fuel efficiency and performance.

- Healthcare: 3D printing is used to create custom prosthetics, dental implants, and even organs for transplantation.

- Automotive: Car manufacturers utilize 3D printing for prototyping parts and producing lightweight components.

- Fashion: Designers are harnessing 3D printing to create unique apparel and accessories, pushing the boundaries of traditional fashion design.

The Future of 3D Printing

As technology continues to evolve, the potential for 3D printing is limitless. We can expect advancements in materials science leading to stronger and more versatile materials, as well as improvements in printer capabilities. Furthermore, as industries increasingly adopt this technology, we will see its integration into supply chains, reducing lead times and enhancing efficiency.

In conclusion, 3D printing is not just a trend but a transformative technology shaping the future of manufacturing. With its myriad of benefits and applications, it is poised to drive innovation across industries and redefine how we think about production.

For more articles on cutting-edge technologies, subscribe to our newsletter or follow our blog!