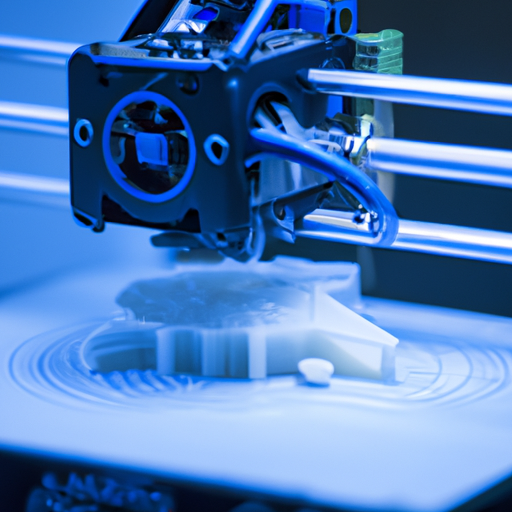

3D printing technology has revolutionized the manufacturing landscape, offering unparalleled customization and efficiency. With its roots in the 1980s, 3D printing, also known as additive manufacturing, has evolved rapidly and now encompasses a wide range of industries including healthcare, automotive, and aerospace.

Recent Innovations in 3D Printing

Today, several innovative advancements have emerged in 3D printing technology. One of the most notable is the development of bioprinting—a method utilized for creating tissue and organ structures using living cells. This groundbreaking technology has the potential to address the global shortage of organ transplants.

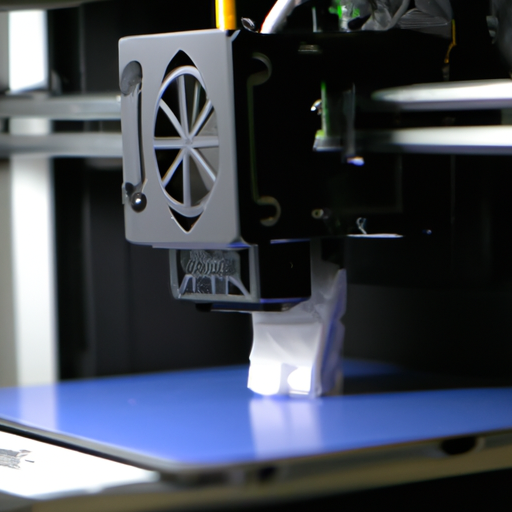

Another significant advancement is the introduction of new materials, such as metal powders and composite filaments, which enhance the strength and durability of printed objects. These materials expand the possibilities for industries that require robust and resilient components.

The Benefits of 3D Printing in Manufacturing

The rise of 3D printing presents numerous advantages over traditional manufacturing methods:

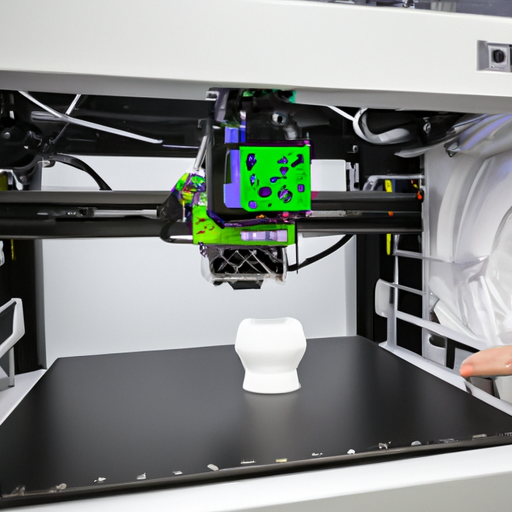

- Customization: Products can be tailored to meet specific requirements, leading to greater customer satisfaction.

- Reduced Waste: As an additive process, 3D printing minimizes excess material usage, making it more environmentally friendly.

- Cost-Effectiveness: Lower production costs and shorter lead times significantly enhance competitiveness in the market.

Future Prospects for 3D Printing Technology

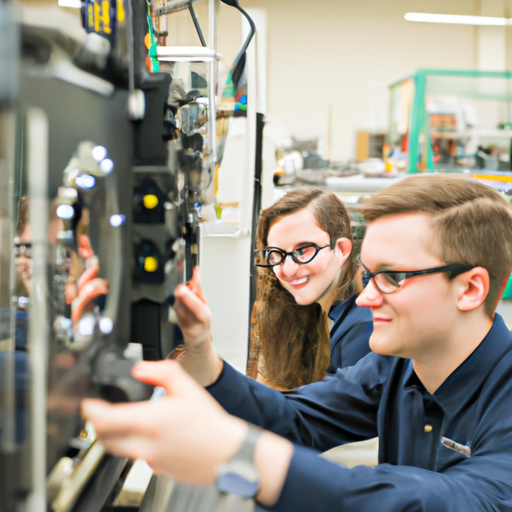

The future of 3D printing looks promising, with continued investment in research and development. The integration of artificial intelligence and automation into 3D printing technology will likely lead to smarter production systems that can further streamline operations.

As 3D printing keeps advancing, businesses across various sectors will need to stay informed and adapt to these changes to remain competitive. The potential for innovations, especially in sustainability and personalized manufacturing, seems limitless.

Conclusion

In conclusion, 3D printing is not just a trend; it’s a transformative technology that is shaping the future of manufacturing. As we witness these incredible innovations, the possibilities for what can be achieved through additive manufacturing continue to expand.

Stay tuned for more updates on the latest in 3D printing technology!