In the rapidly evolving world of technology, Digital Twins have emerged as a revolutionary concept that is reshaping industries. But what exactly is a Digital Twin? In simple terms, a Digital Twin is a virtual representation of a physical object, system, or process. This digital replica allows businesses to simulate, analyze, and optimize their operations in real-time.

The Evolution of Digital Twins

The concept of Digital Twins first gained traction in the manufacturing sector but has since expanded into other industries such as healthcare, transportation, and energy. With advancements in IoT (Internet of Things) technologies, creating and maintaining Digital Twins has become more accessible and practical.

Key Benefits of Digital Twins

Digital Twins offer numerous advantages, including:

- Predictive Maintenance: By continuously monitoring the performance of physical assets, Digital Twins can predict when maintenance is needed, reducing downtime and costs.

- Enhanced Decision-Making: Real-time data provided by Digital Twins enables organizations to make informed decisions quickly, enhancing agility and efficiency.

- Improved Product Development: By simulating products in a virtual environment, businesses can identify potential issues and optimize designs before physical production.

Applications of Digital Twins

Digital Twins can be utilized across various sectors:

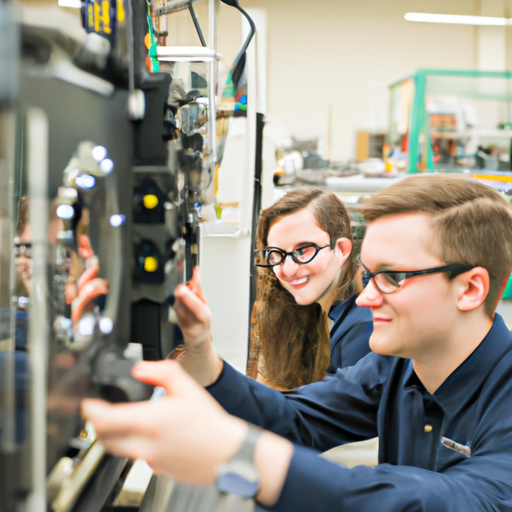

- Manufacturing: Used for monitoring and optimizing production lines and processes.

- Healthcare: Helps in personalized medicine by simulating individual patient responses to treatments.

- Smart Cities: Digital Twins of urban infrastructure can aid in better planning and resource management.

The Future of Digital Twins

As we look ahead, the role of Digital Twins is expected to grow significantly. Integration with artificial intelligence and machine learning will enhance their capabilities, making them more predictive and prescriptive. Industries are starting to recognize the importance of investing in this technology to stay competitive.

Final Thoughts

In conclusion, Digital Twins represent a transformative technology with the potential to significantly impact how businesses operate. By leveraging real-time data and predictive analytics, organizations can enhance efficiency, improve customer experiences, and drive innovation.

As technology continues to evolve, embracing concepts like Digital Twins will be crucial for organizations aiming to thrive in the digital age. Are you ready to explore the possibilities of Digital Twins in your industry?

For more insights on technology trends, stay tuned to our blog!